Case Study: PTO Sub-Assembly

The Customer Pain

- Complete PTO Sub-assembly Removal With Every Seal Replacement

-

Lack Of Seal Installation Training

- Caused Issues On The Assembly Line

- Lack Of Support From Seal Supplier

The ESP Solution

ESP Reengineered PTO Sub-assembly

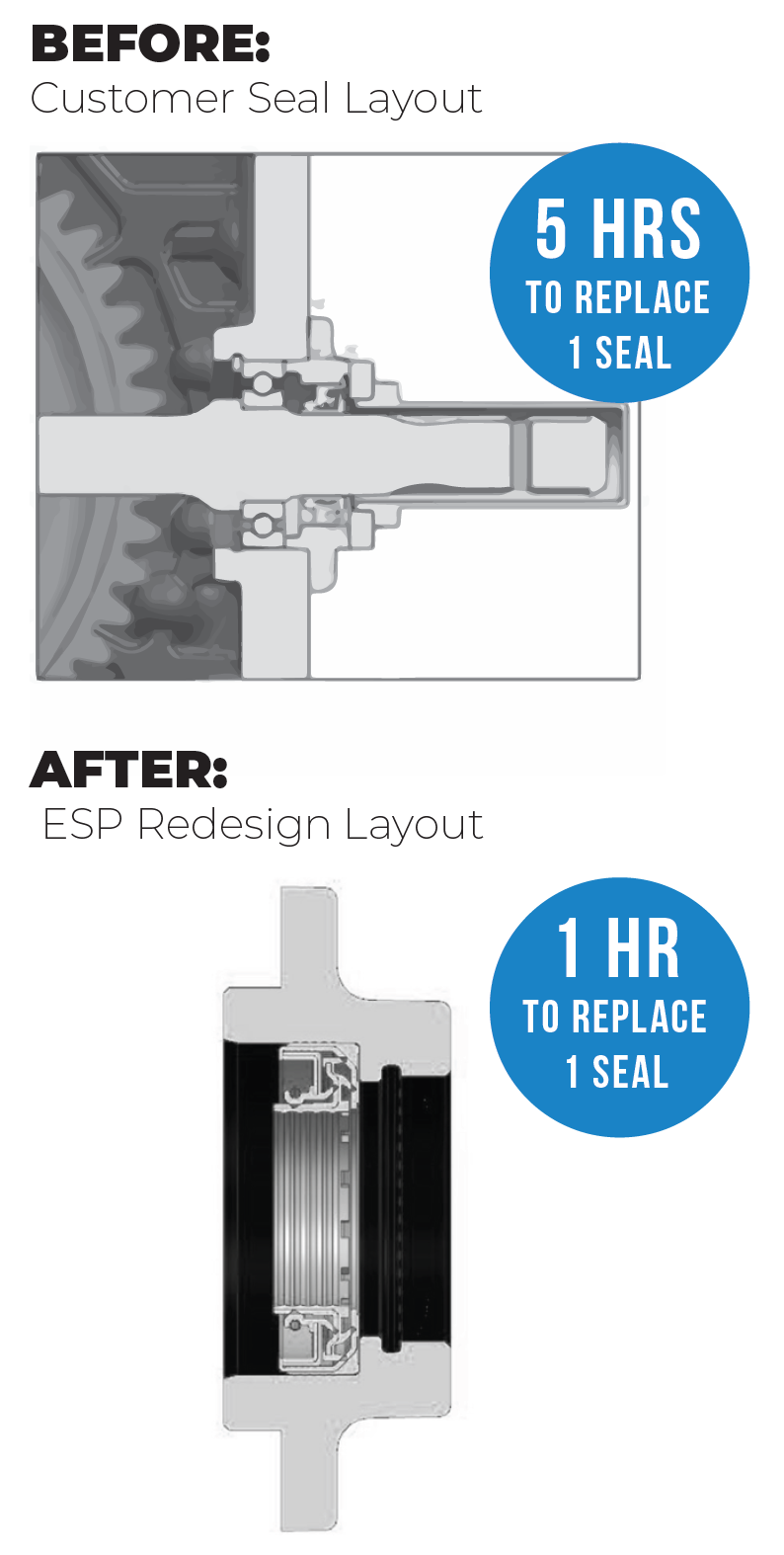

ESP Engineering team comprehensively redesigned the PTO sub-assembly, introducing an independent cover design for the PTO seal and bearing. This innovative approach eliminated the need to completely remove the PTO sub-assembly every time a seal was replaced.

By working with ESP, the customer added seal experts as an extension to its engineering team.

The Impact

- Service Cost Reduction

- Engineered Seal Support