Parker Urethane D-Rings

Parker’s Resilon polyurethane D-ring is a one-piece hydraulic valve sealing solution which delivers longer life and reduced warranty costs over traditional multiple-component seals.The molded “D” shape which is higher in the middle and lower on the ends, provides sealing in critical areas while reducing the chance of a seal being cut during installation. Its sealing lip contact footprint is minimized, thus reducing the amount of friction between seal and bore while providing expected sealing performance. The “D” shape is symmetrical so there is no performance degradation as the valve cycles in the reverse direction nor concern of backward installation of the seal. The design also incorporates “pressure pedestals” to eliminate the potential for “blow-by,” common in reverse cycling.

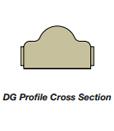

DG Profile, Urethane D-Ring

Technical Data