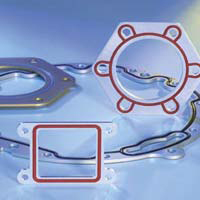

Plate seals are hybrid seals designed to incorporate the best features of flat gaskets and O-rings, while eliminating the drawbacks associated with each of those sealing methods. Plate seals originally gained their reputation for reliability by solving the critical sealing demands of the aerospace industry. Plate seals typically use aluminum or steel carriers with a groove machined into the face and a rubber sealing bead molded into the groove. The two main types of plate seals include groove-bonded and edge-bonded seals.

Ease of Installation

- Rigid seals are easy to handle and install, particularly in blind or vertical installations

- Color-coded seal edges help ensure correct part identification

- Offers visual confirmation of seal installation

- Seal is chemically and mechanically bonded to mating surface and cannot be dislocated

- Metal-to-metal contact prevents over-squeeze of seal and eliminates need to retorque bolts

- Requires less sealing force than flat gaskets

- The rigid structure enables automated installation in higher-volume applications

Cost Advantage

- Reduces expensive machining required on mating components

- Single plate/multi-port sealing capabilities reduce inventory, increase manufacturing productivity, and minimize

- warranty costs due to missing or poorly installed sealing elements

- Allows high pressure sealing without requiring backup rings

- Can reduce the amount of elastomer required, proving even more economical for high-cost elastomers

Performance

- Controlled squeeze metal-to-metal contact prevents over-compression, which is known to cause premature seal degradation.

- Plate seals have the potential of reducing elastomer exposure and lessening fluid/swell issues