Click on the image to open in a New Tab.

Video Transcript

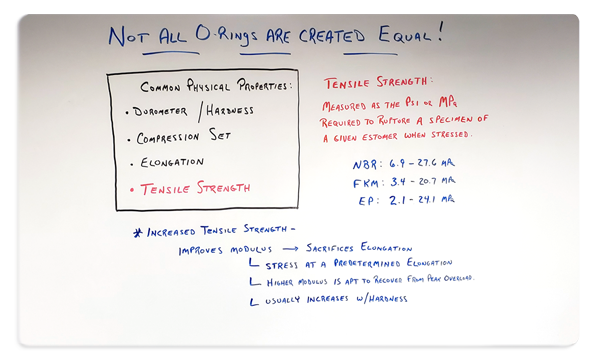

What Is Tensile Strength & Why Is It A Factor?

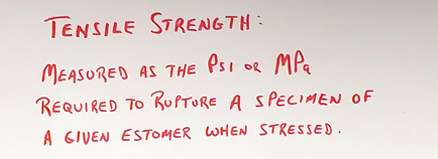

Short version according to the Parker Hannifin O-ring Guide:

Tensile strength is simply measured as the PSI or megapascals required to rupture a specimen of a given elastomer when stressed.

Put it under stress and at what point does it burst – at what point does it break?

One thing I want to point out, as I’ve done this in other sections regarding compression set and elongation, it varies by material, but it also varies within the material. Which is why I emphasized that they’re not all created equal. A nitrile isn’t just a nitrile, isn’t just a nitrile.

Specific to tensile strength, it can range anywhere from 6.9 to 27.6 megapascals. Just within the nitrile family alone. FKM can very 3.4 to 20.7 – a pretty good size range. Even EP which tends to be a fairly simple, stable material in most applications – 2.1 to 24.1 megapascals.

What Am I Giving Up When I Improve My Modulus?

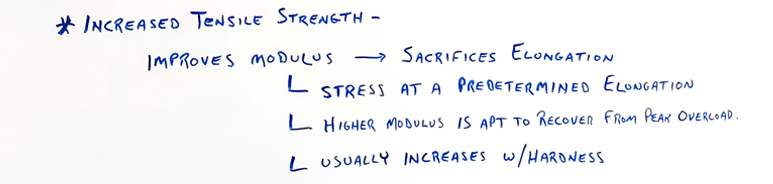

Why is that important? In the grand scheme of things, as you increase tensile strength, you improve the modulus of the material. As stated in other sessions, when you make a change to a compound or material, to get something you’ve got to give up something.

What am I giving up when I improve my modulus?

I’m sacrificing elongation. In most applications that’s a non-factor. As we’ve talked to the elongation section, elongation is predominantly about installation. How far can it stretch? If you’re not having to overstretch your o-ring, it’s less of a factor but rather gives you some important properties.

With the modulus – which is the stress at a predetermined elongation usually measured at 100% – the higher modulus is apt to recover from peak overload. That’s important. It helps support and aid to the strength and wear-ability of the o-ring and it usually increases with hardness.

Tensile strength while not talked about a lot can be an important factor and one of those key physical properties that you need to be aware of as you evaluate why and how all o-rings are not created equal.