Whitepapers On Whiteboard

Summary

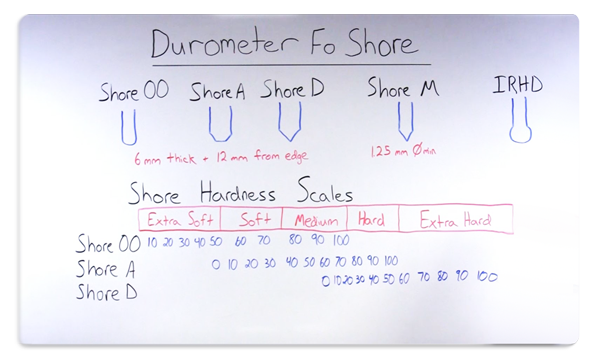

Today we’re going to talk about durometer of rubber products. Durometer is a measurement of hardness and like other hardness test measures the depth of indentation in the material created by a given Force using a standardized pressure foot. The ASTM D 2240 standard recognizes 12 different durometer scales.

Click on the image to open in a New Tab.

Video Transcript

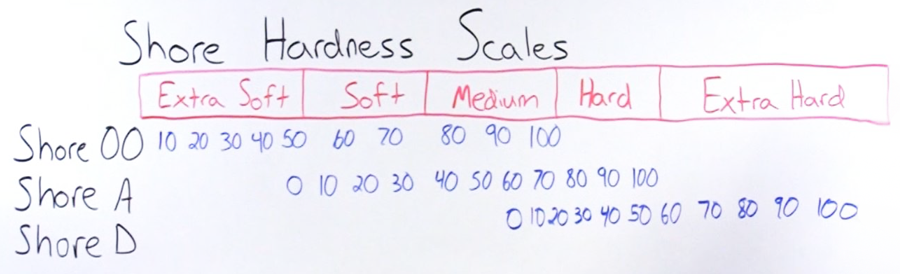

Shore Hardness Scales

Shore OO Durometer Scale:

If we look at some of the most common scales used across the industry, we can start with the Shore OO The indenture for the Shore OO is the conical bottom there in this scale is used for extra soft rubbers. Some examples of this would be like sponge rubber or Gummy Bears or even the gel insoles for your shoes.

Shore A Durometer Scale:

Another very common durometer scale used in the industry is the shore A durometer scale. You can see that the indenture for this one is a truncated cone. This durometer scale is going to cover your soft medium and hard rubbers. Some soft rubbers could be like rubber bands or a pencil eraser. Some more medium hardness rubbers would be car tires or a little bit harder than that, maybe the sole of your shoe.

Shore D Durometer Scale:

And then after that, for much harder materials, we’re going to jump up to the shore D. You can see this is a 30-degree cone. Some examples of products you would use the shore D hardness tester on would be like a shopping cart wheel, which is a very hard rubber or even some plastics when you get to the higher range of the shore D – like a hard hat or something like that.

IRHD Durometer Scale:

Another very common durometer scale used in the industry is the IRHD – the international rubber hardness degree. This scale is very closely aligned with the shore A but it is not exactly equivalent. We can’t compare an IRHD to the shore A and think that their equivalent.

Important Note For Testing:

One important aspect to note is the test methods used when testing durometer.

When you’re using any of these Shore OO, Shore A , or D, or the IRHD scales, you need to be using a large thick flat piece of rubber. The piece of rubber needs to be a minimum of six mm thick and large enough that all of your measurements can be taken at least 12 mm from the edge of the material. This can create some obstacles when you’re trying to measure small rubber products such as o-rings. Most O-rings don’t have a 6 mm thickness. So if you’re trying to use a Shore A durometer tester on the typical o-ring that’s going to be an incorrect measurement method. It’s not valid.

Shore M Durometer Scale:

In the case that you do need to measure physical parts with small cross sections, you’re going to have to use the shore M durometer scale. Again, you can see that this is a 30 degree cone. It is a little bit smaller diameter than the short D and also would have a different spring force applied to it. But with this scale you can measure samples as little as a 1.25 mm in diameter.