Seal Design for 3000 PSI Ag Application

Situation

Agriculture equipment manufacturer is having inconsistent performance from their hydraulic cylinder source and wants to bring cylinder production in house.

Critical Business Issue

With expertise in metal fabrication and machining the customer primary need was advice on seal design and application support. They have a need to seal pressure to 3000 PSI and are looking for the smooth operation of the hydraulic system without loss of operating pressure.

Reason

Standard seal package does not consistently perform at high pressure and pressure spikes and sometimes allows for piston “drift.” Pressure and stroke were standard at 3000 PSI and 12-24″ stroke.

Capability

Customer assigned engineering lead to the project and selected ESP International to optimize design to meet performance, assembly and cost criteria. Customer expertise was in machined components that made design to high standard attainable with quality workmanship and the right seal design.

We provided

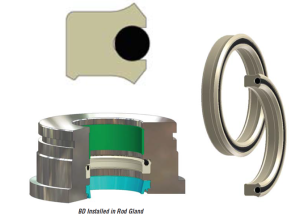

To address the “drift” of the piston ESP recommended the utilization of a T-Seal piston seal that assures better seal force than the standard “slipper seal” that incorporates a PTFE cap as the primary seal. Wear rings were incorporated into the piston to maintain concentricity for side load conditions to allow for a lower cost “slipper seal” option on the piston.

The seal design incorporates a standard Parker BD rod seal utilizing the seal effectiveness of the PPDI urethane 4300 material. However, to assure cold temp sealability the addition of a spring loader to the BD lip configuration maintained the necessary lip load in temperatures to -40F.Aggressive Hytrel material was selected as the material for the wiper and backup requirements.

Result

In-house production of hydraulic cylinders for the planters to operating pressure of 3000 PSI with no drift or leakage in a cost effective seal package.