Parker JM Clipper® Seal

Whitepapers On Whiteboard

Video Transcript

Welcome to our next installment of ESP’s “Not All Seals Are Created Equal.” Today we are going to talk about a seal that’s been around for a long time, but in some cases may be one of the best-kept secrets in the utilization of rotary shaft seal applications. And that is the Parker JM Clipper® seal.

Standard Oil Seals

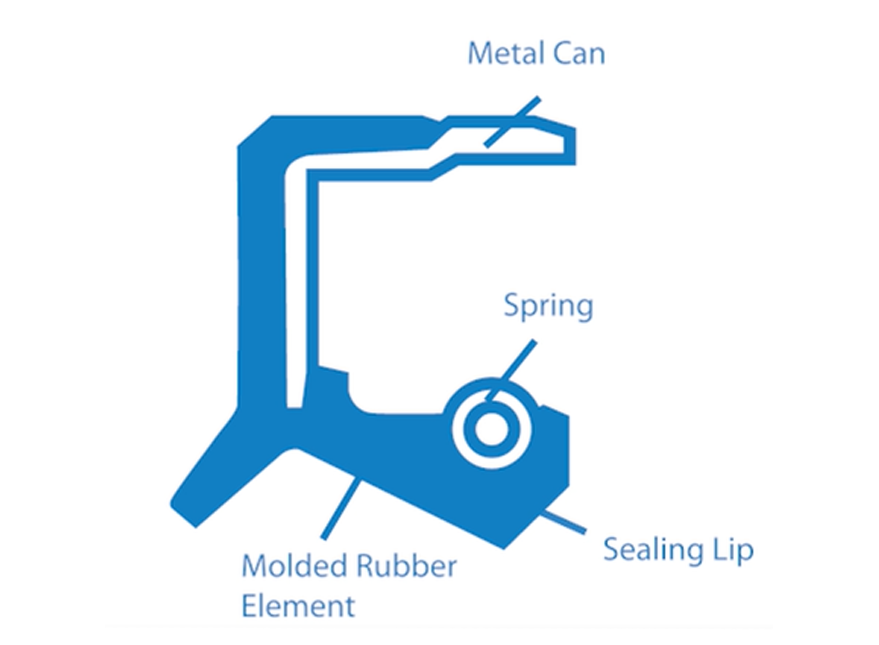

What makes the JM Clipper® seal a little unique is that when we think of radial shaft seals, oil seals, we think of a metal can on the OD with a rubber element that has been molded to it that acts as the sealing element. Sometimes it has a spring to help provide the necessary pressure on the sealing lip – the necessary load – to allow it to function properly.

Parker JM Clipper® Seal

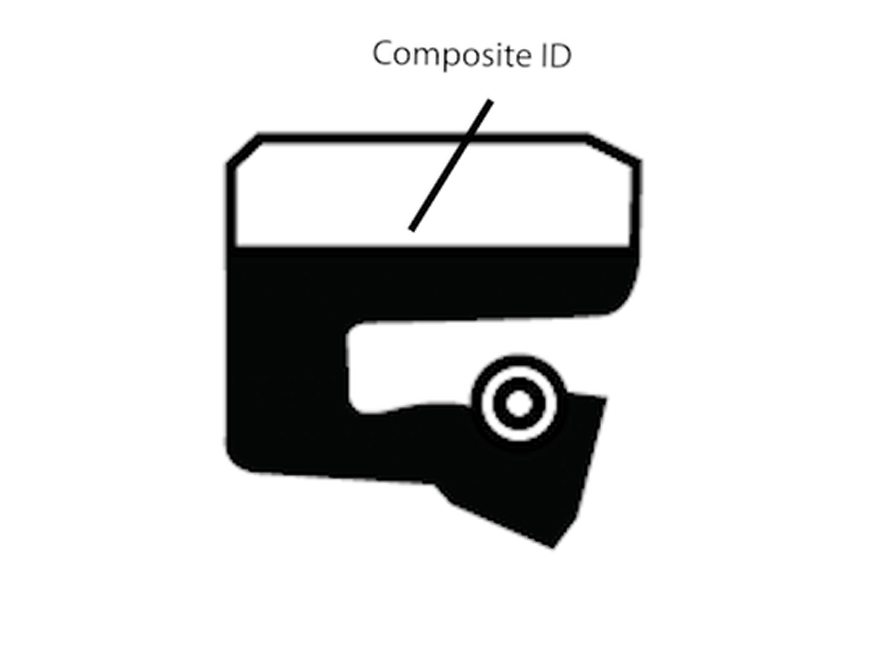

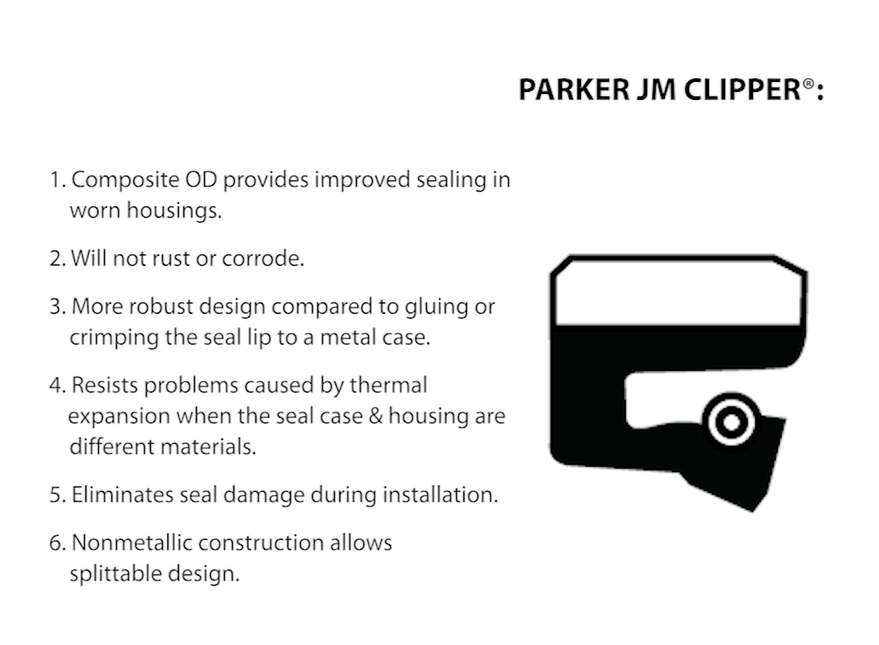

With the Clipper® seal you have a composite OD that is integral with and molded with, the elastomeric sealant component – can also have a spring to it for added load. Many of the same characteristics as what the traditional metal seal would be. So very robust seal and it provides a lot of rather unique benefits and features from the normal oil seal. Let’s take a look at a few of them.

- As mentioned, the composite OD already provides a gasket type seal. So, it exactly does perform as a sealing element as opposed to just metal-on-metal and it does not require any type of plates or secondary components to keep it in place.

- It’s composite so it’s not going to rust or corrode – creating contamination issues.

- It is a one-piece molded construction for the entire size range, which makes it a little bit more robust than the normal mechanical crimping or in some cases adhesive gluing of the rubber to the outer can.

- It eliminates a lot of the problems of thermal expansion when you have extreme heat, extreme cold, and metal-on-metal – sometimes losing some of that friction fit that is necessary for the oil seal to stay in place and perform.

- It is much easier to install and is very user-friendly.

- It is also able to be designed for split models as well.

The Parker JM Clipper® seal has been around for a long time. It’s utilized in a lot of different industries, a lot of different applications, and one that wanted you to be aware of.

If you have any questions or need more information regarding the JM Clipper seal, please contact ESP International, check out our website and learn more.