Click on the image to open in a New Tab.

Video Transcript

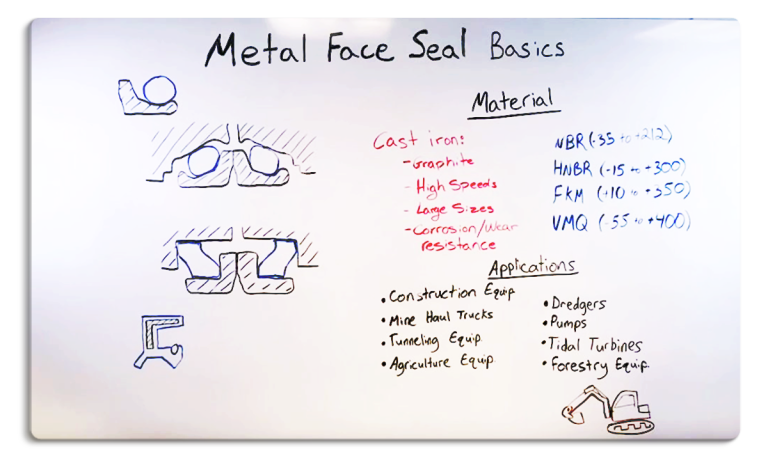

Metal Face Seal Components

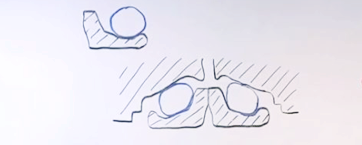

Today we’re going to talk about Metal Face Seals, otherwise known as duo-cone seals. What they consist of is two metal rings and two large o-rings, or toric rings. They come in seal sets. This would be one half of the seal set – one metal ring and one o-ring. Each half is then installed into the housing [you can see here] and then the two halves of the housing are brought together and it creates an axial load between the metal seal rings. So the actual dynamic movement will be between the two metal rings. You’ll have one side of the housing that is stationary and one side of the housing that rotates. There is no relative motion between the seal ring and the o-ring or between the o-ring and the housing.

Profile Options

They come in a couple different profile options:

- Traditional Duo-Cone Style

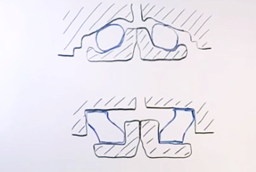

- The Trapezoidal Elastomer Ring Style

Some advantages of the trapezoidal rings style would be that you get to machine just a square step in your bore to receive the seal rather than machining in this complicated geometry that’s necessary for the duo-cone option. These types of seals are very heavy duty. They’re used in extreme service environments where you would not be able to use a traditional elastomer lip style seal. They just wouldn’t survive. The contaminants are too harsh and they would chew that style of seal up.

Materials

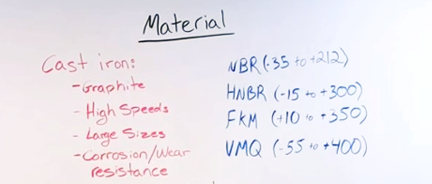

Some of the different material options that we have available for the METAL RINGS

- we use cast iron for ours with graphite inclusions in there. This allows us to run at higher speeds than the steel forged counterparts that are out there on the market as well. We’re able to do anywhere from very small two very large sizes (50 mm up to 1-1/2 meters. The cast iron is also very corrosion and wear resistant as well.

Some of the different material options that we have available for the ELASTOMER OR TORIC RINGS

- are the NBR material. It’s got good oil compatibility and compression set resistance. If we need to we can bump up to an HNBR that gives you a little bit higher temperature capability and also gives you some ozone resistance as well. If we need a higher temperature yet, then we’ll jump up to FKM, but you do sacrifice a little bit of that low temp capability versus the NBR or HNBR. If you’ve got very high-temperature extremes from very low or to very hot, we can go to silicone but with silicone, we have to take special consideration with the type of oil that you use.

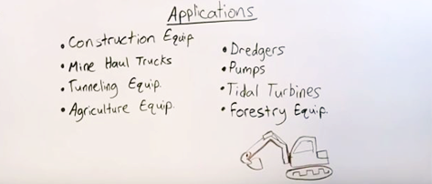

Applications

These types of seals are used in a wide variety of applications – most commonly in the construction field. Your bulldozers or your excavators – anything with a track drive is typically going to use these metal face seals. But they’re used in a variety of other applications as well; mine haul trucks, they’ve got tunnel and boring equipment that use these a lot, we’re getting into the agriculture market more, and even some offshore applications as well with dredgers and tidal turbines also a good fit for the seals as well and pumps.