WRT Profile, Tight-Tolerance Rod Wear Ring

Back to top↑

WRT profile tight-tolerance rod wear rings, when combined with the WPT profile, complete the premier cylinder bearing system. Recommended for light- to heavy-duty hydraulic applications, they are available in standard sizes from 7/8″ up to 7″ rod diameters (larger sizes upon request). WRT profile wear rings feature chamfered corners on the O.D. and are designed to snap open during assembly to hold tight against the head gland, eliminating rod interference and simplifying installation.

Technical Data

Standard Material: W4733 WearGard™

Radial Tolerance: +.000″/-.002″ (up to 5-3/4″ I.D.); +.000/-.003″ (5-3/4″ to 7″ I.D.)

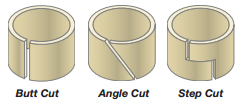

End Cuts: Butt Cut, Angle Cut (Skive Cut), Step Cut