Radial Shaft Seal Dynamic Runout (DRO)

What is Radial Shaft Seal Dynamic Runout?

Dynamic runout is where the center of the shaft is offset from the true center of rotation. The shaft, instead of rotating true, has a wobbling effect.

How Can We Prevent Radial Shaft Seal Dynamic Runout In Our System?

- Make sure your design includes bearings. Bearings are a good way to stabilize the system and make it so the shaft will run true. If we have bearings near our sealing surface, that'll help limit the amount of runout the seal will see.

- Choose specific seals to help accommodate. A convoluted lip seal is more flexible and allows us to accommodate dynamic runout because as the shaft is rotating or wobbling, this seal lip can follow the shaft much easier than your traditional lips.

Dynamic runout is the only misalignment that's dynamic. So, it's critical as runout increases; to run at lower speeds. Otherwise, the seal will not be able to follow the shaft as it's wobbling at those higher speeds and will create little pockets, or gaps, within the shaft seal interface and cause a leak.

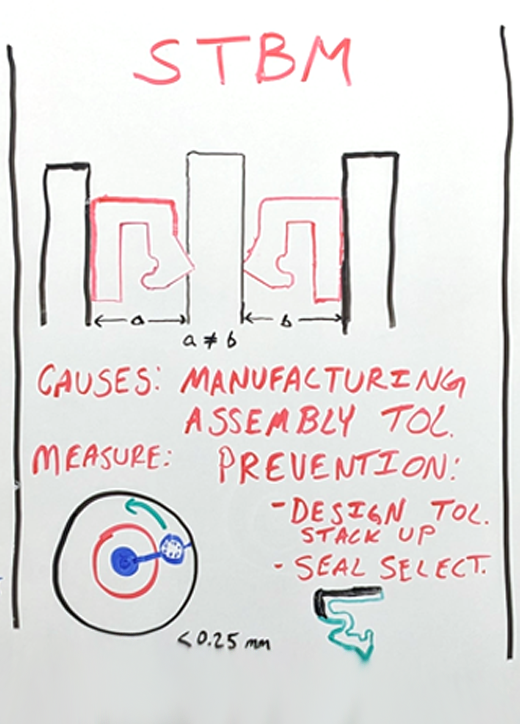

Radial Shaft Seal Shaft-to-bore Misalignment (STBM)

What is Radial Shaft Seal Shaft-to-bore Misalignment?

Shaft-to-bore misalignment is an offset from the center of the shaft to the center of your housing. In that case, it will have a lot of loading from the seal on one side vs. the opposite side.

What Causes Radial Shaft Seal Shaft-to-bore Misalignment?

- Mainly Manufacturing

- Assembly Tolerances & Stack-ups

What Ways Do We Measure Radial Shaft Seal Shaft-to-bore Misalignment?

Place the base of a dial indicator on the shaft and the dial surface on the surface of the bore. Slowly rotate the shaft and let it follow the housing. Take the reading from the dial indicator. It's recommended to keep the shaft-to-bore misalignment below 0.25mm.

How Can We Prevent Radial Shaft Seal Shaft-to-bore Misalignment In Our System?

- It is heavily influenced by the design and the stack-up of your assembly when designing your system.

- Use specific seals, such as a convoluted lip.

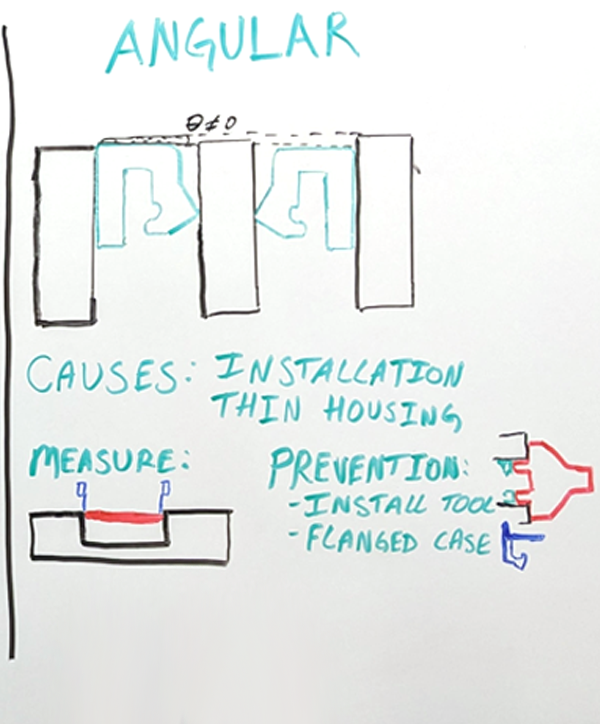

Radial Shaft Seal Angular Misalignment

What is Radial Shaft Seal Angular Misalignment?

Angular misalignment is when the face of the radial shaft seal is not perpendicular to the shaft. The seal is not installed flush with its housing.

What Causes Radial Shaft Seal Angular Misalignment?

- The main cause is installation

- Or a thin or flexible housing with some motion during the application that causes the offset.

What Ways Do We Measure Radial Shaft Seal Angular Misalignment?

Use a caliper and measure the depth from a known distance. The face of the housing to the face of the seal - and again on the opposite side a couple of times around the seal. See the difference between the face of the seal on one side to the other. Ideally, it is flush, and you'll have a reading of 0.

How Can We Prevent Radial Shaft Seal Angular Misalignment In Our System?

- Use installation tools. The tool will bottom out on the housing or bottom out on the shaft. This allows a reference surface or a hard stop to ensure the seal is perpendicular to the center rotation.

- If this isn't an option, look at a flange case design.

A radial shaft seal flange case has an extrusion on the case, pointed outwards. When you install this flush, the flanged case will hit the face of the housing; therefore, you know that it's perpendicular to the shaft.

Why Is It So Important That We Look For Radial Shaft Seal Misalignment?

Because the interference of the seal lip is critical to its life. If we have more interference on one side than the other, it will lead to several issues in your system. An increase in any of these misalignments ultimately leads to an increase in your underlip temperature, generating more heat and more contact from the seal on the shaft and will generate higher torque and eventually consuming more power from the seal. When we have higher interference, we get premature wear or additional wear. And in cases like shaft-to-bore misalignment, the wear is acentric – an extreme amount of wear on one side, and the opposite side will hardly have any wear.